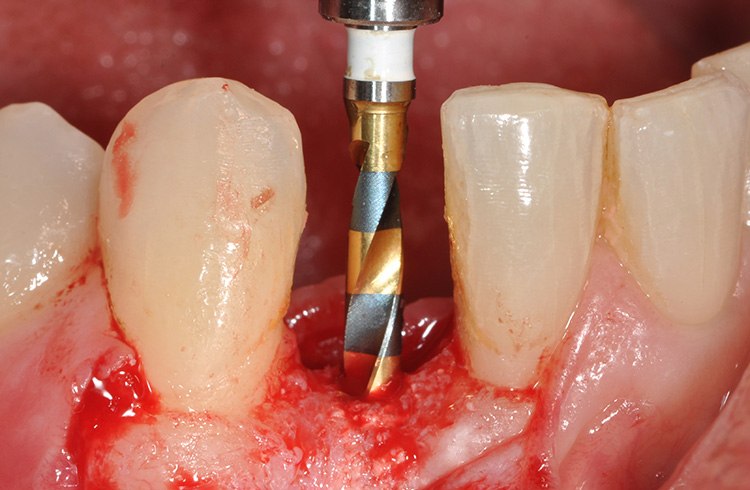

The success of dental implants relies on bone adaptation to the titanium implant. Heat generation causes bone die back beyond the osteotomy over the subsequent weeks after implant placement. Minimizing heat generation will lead to less die back and greater stability of implants for immediate/early loading.

Over-heating bone during an osteotomy is the #1 cause of surgeon related failure

There are many different manufacturer recommendations when it comes to speed of running your osteotomy drills for implant placement. Most recommendations range from 1200-3000 RPM.

Thankfully, like most things in implantology this has been studied.

The following is a review of such an article out of the Journal of Oral and Maxillofacial Surgery from way back in 2002 by Sharawy et al. entitled

Heat Generation During Implant Drilling: The significance of Motor Speed.

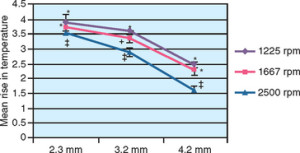

The researchers compared several implant systems with internal and external irrigation and measured drilling time, time needed to return to a baseline temperature after osteotomy at 3 different RPM:

1225, 1667 and 2500RPM.

Results show that the mean rise in temperature of the adjacent bone was significantly lower at a drill speed of 2500 compared to the other to RPM and the slowest RPM, 1225, had the most heat generated.

Additionally, the time it took for the bone to return to it’s baseline temperature was significantly lower at the higher RPM than the slower RPM.

Take Home Points:

- Do everything you can to keep the bone cool.

- Drill at 2500RPM

- The longer it takes to drill, the longer it takes for the temperature to return to baseline.

- Use sharp osteotomy drills. Establish a system where you don’t re-use burs beyond their lifespan.

- Interrupt the drilling procedure every 5 seconds for at least 10 seconds while irrigation is applied.